The large range automatic checkweigher can detect on-line whether there are overweight/underweight weight deviation abnormalities in the packaged product, and can feedback information to the filling or packaging equipment; at the same time, it can detect bags, bags, boxes, cans, bottles, boxes and other packaging Abnormalities such as the number of products or missing accessories. Ensure that the net content of the product meets the specifications and requirements, save material costs, improve product quality and integrity, and avoid user complaints.

The large range automatic checkweigher can detect on-line whether there are overweight/underweight weight deviation abnormalities in the packaged product, and can feedback information to the filling or packaging equipment; at the same time, large range checkweigher can detect bags, bags, boxes, cans, bottles, boxes and other packaging Abnormalities such as the number of products or missing accessories. Ensure that the net content of the product meets the specifications and requirements, save material costs, improve product quality and integrity, and avoid user complaints.For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

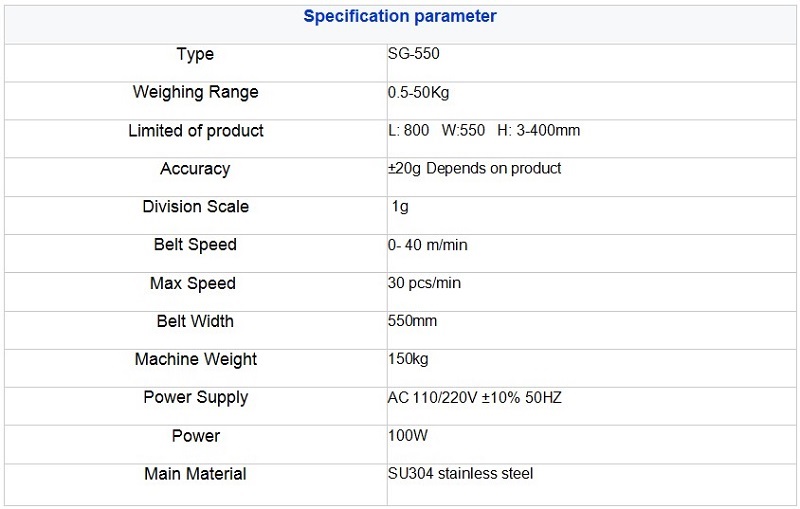

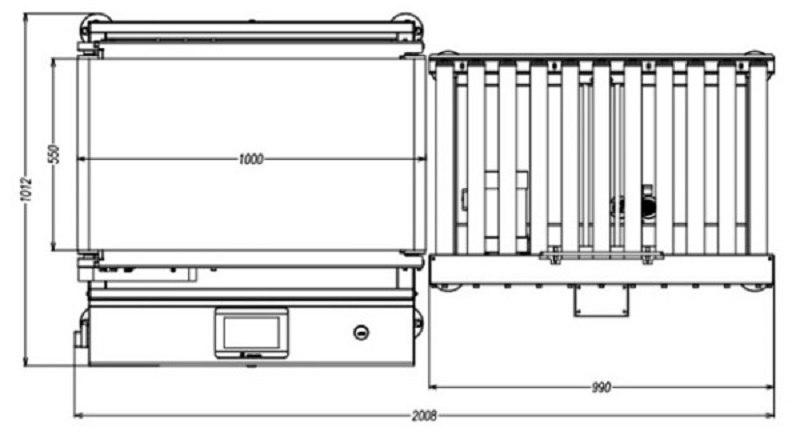

Note 1: The above specifications are standard specifications, other sizes can be customized according to customer needs.

Note 2: The above detection sensitivity is the surface accuracy of the empty conveyor belt. The actual detection sensitivity is affected by the product to be tested, the use environment, or the location of the metal mixing.

Weighing method: German HBM load cell

Control system: Shanghai Shigan independently developed a single-chip microcomputer system;

Equipment material: all stainless steel structure;

Conveyor belt height: The height of the conveyor belt from the ground is customized according to customer requirements;

Conveying direction: Facing the operation panel, from left to right or right to left, customized according to requirements.

Operating environment: -10°C to +40°C (relative humidity 30 to 85%, non-condensing)

a. Standard SUS304 stainless steel body, in line with various safety regulations for food and pharmaceutical production

b. Fast belt replacement system, easy to clean the conveyor belt

c. High-precision imported sensors and motors ensure the high precision and high speed of the automatic checkweigher

d. There are 100 commonly used product presets; simple product editing and storage functions.

e. Fast product switching and automatic adjustment of the sorting speed of corresponding products.

f. Color touch screen integrated control, man-machine interface operation is simple and convenient.

g. The input and output of external equipment realize online function, which can carry out various controls

1). Barcode scanner signal input

2). Printer, inkjet printer, labeling machine output

3). Feedback weight signals to packaging machines, automatic filling machines and other equipment to implement closed-loop control

h. Automatic zero tracking technology

i.U disk data storage, unlimited storage of production data, and statistical functions such as histogram, sliding average, and standard deviation, which are convenient for customers to read and make various production adjustments at any time

Large range custom checkweigher application range: food, medicine, chemical industry, logistics, packaging, clothing, electronics, plastics, daily necessities and many other fields, packaging lines and logistics storage weighing, can detect bags, bags, boxes, cans, bottles, boxes Abnormalities such as the number of products in the package or missing accessories.

Reviews

There are no reviews yet.