The SG-150H high-speed automatic checkweigher has a detection accuracy of ±0.1g, and 120-160 bottles per minute can accurately weigh and detect and reject NG products. Shanghai Shigan bottled checkweigher can realize the detection of the net weight of the bottle, the detection of missing bottles in the whole box, and the detection of missing bottled product accessories.

Type: SG-150H

Weighing Range: 3-500g

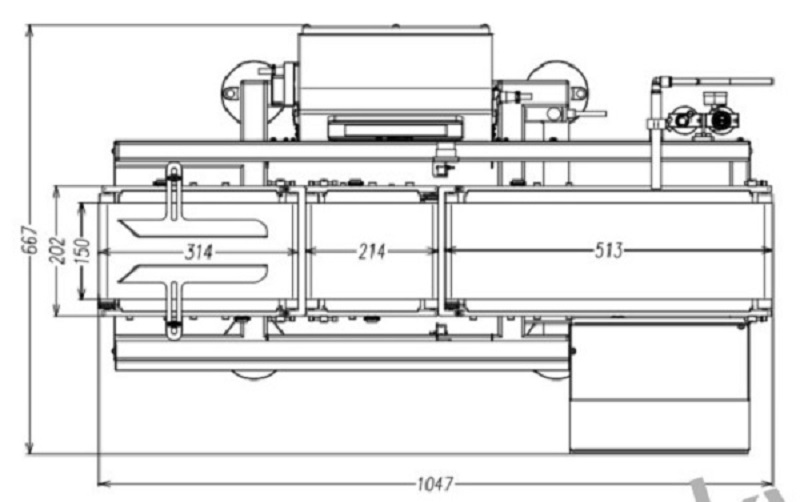

Limited of product: L: 100 W:150 H: 3-150mm

Accuracy: ±0.1g Depends on product

Division Scale: 0.1g

Belt Speed: 0- 90 m/min

Max Speed: 160 pcs/min

Belt Width: 150mm

Machine Weight: 60kg

Power Supply: AC 110/220V ±10% 50HZ

Power: 100W

Main Material: SU304 stainless steel

Options and accessories:

Sorting or rejection device, front conveyor, guide rail

External interface: RS232/RS422/RS485, USB, voltage signal or switch signal, TCP/IP

Online printer

Back-end printer

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. Support multiple languages: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (customer specified), the default is Chinese and English.

3. Online weight checker can store 200 kinds of product inspection data, which is convenient for users to call.

4. The USB data storage interface can transfer report data to a PC for analysis and printing.

5. Parameter setting password protection, only management personnel operation.

6. Automatic zero point system to ensure reliable detection data.

7. Built-in temperature and noise compensation system to ensure system stability. Online printing function (customization required).

8. Data external communication interface, which can be connected to other equipment in the production line (eg: labeling machine and inkjet printer) (customization required).

9. Multiple rejection devices: push rod rejection, fall rejection. (Customer required).

10. Simple mechanical structure, easy to disassemble, clean and maintain.

Reviews

There are no reviews yet.